Birch Plywood Grades

Birch plywood is a strong, durable, and versatile material made by gluing together thin layers of birch veneer. Its stability and high-quality finish make it a popular choice in construction, furniture-making, and interior design.

Birch plywood is classified into different grades based on surface quality and defects. These grades follow EN and international standards, helping buyers choose the right type for their needs.

Birch Plywood Grading System

| Grade | Code | Description |

| Elite (Highest Quality) | E, A | Smooth and flawless surface, ideal for high-end furniture and decorative use. |

| First | 1, I, B | Minor imperfections, suitable for furniture and visible surfaces. |

| Second | 2, II, BB | More noticeable defects, commonly used for interior applications. |

| Third | 3, III, CP | Visible knots and repairs, used in structural projects. |

| Fourth (Lowest Grade) | 4, IV, C | Rough surface with defects, mainly for industrial use. |

Choosing the Right Grade

Higher grades (E, A, B) are perfect for furniture and decorative applications, while lower grades (CP, C) work well for structural and industrial purposes. Understanding these grades ensures you get the right plywood for your project.

Elite and First Grade Birch Plywood: Understanding the Differences

Elite Grade Birch Plywood

Elite grade is the highest quality birch plywood available, offering a flawless surface with minimal imperfections. It features a smooth texture, uniform color, and no visible knots or voids, making it ideal for premium furniture, luxury interior design, and high-end construction projects. This grade is perfect for applications where aesthetic excellence and top-tier quality are essential, such as:

- Luxury furniture and cabinetry

- High-end wall paneling and decorative surfaces

- Precision woodworking projects

First Grade Birch Plywood

First grade birch plywood maintains high quality but allows for minor imperfections, such as small knots, slight discoloration, or minimal surface irregularities. Despite these minor defects, it remains a durable and visually appealing option for a variety of applications, including:

- Furniture production

- Flooring and wall panels

- Interior design elements

While not as flawless as Elite grade, First grade birch plywood is a cost-effective solution for projects requiring a balance of quality and affordability.

Understanding Birch Plywood Grades: Second, Third, and Fourth

Second Grade Birch Plywood

Second grade birch plywood is a sturdy and reliable option for applications where appearance is not a priority. While it may contain larger knots, small splits, or discolorations, it remains a strong and durable material. This grade is ideal for:

- Packaging and shipping crates

- Pallets and industrial storage solutions

- General construction where aesthetics are not crucial

It offers a cost-effective balance between strength and quality, making it a popular choice in industrial and manufacturing settings.

Third Grade Birch Plywood

Third grade plywood is designed for structural applications where visual imperfections do not matter. It may contain large knots, splits, and other surface blemishes, but it still provides reliable durability. Common uses include:

- Concrete formwork and molds

- Subflooring and underlayment

- Hidden structural elements in construction

This grade prioritizes functionality over aesthetics, making it a preferred choice for projects requiring strength and resilience.

Fourth Grade Birch Plywood

Fourth grade birch plywood is the most economical option, suited for temporary and low-cost applications. It may feature significant defects such as large knots, cracks, and discolorations, but it remains functional and budget-friendly. Typical uses include:

- Temporary hoardings and signage

- Construction site fencing

- Short-term structural applications

This grade is best for situations where cost-effectiveness outweighs the need for strength or visual appeal.

Custom Birch Plywood Solutions for Specific Applications

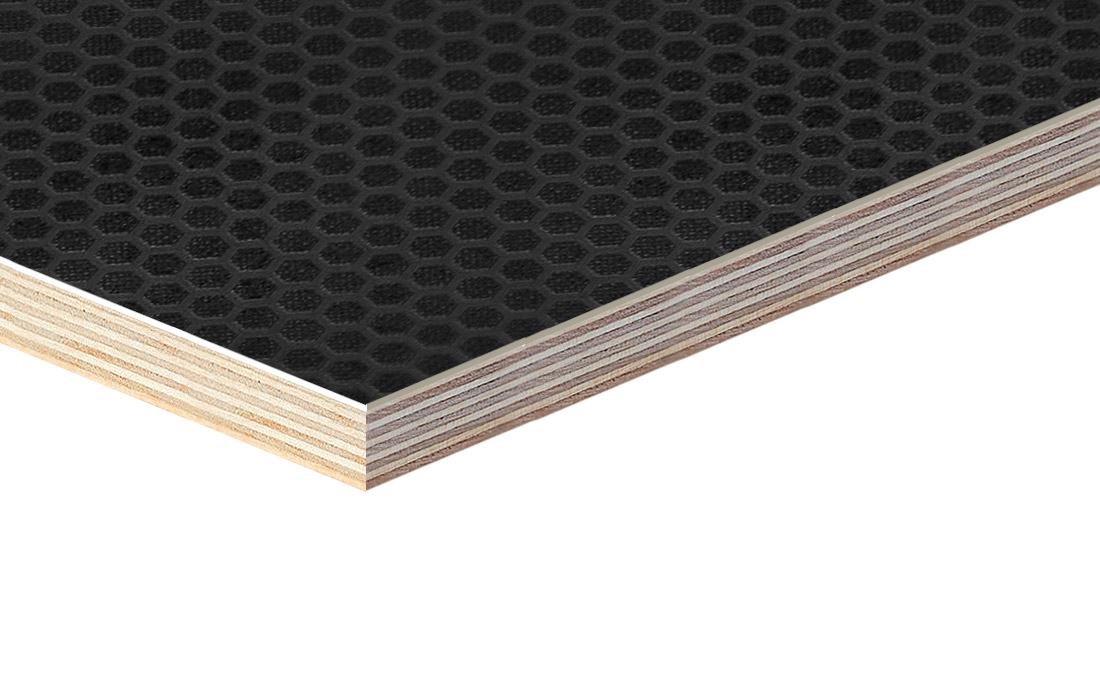

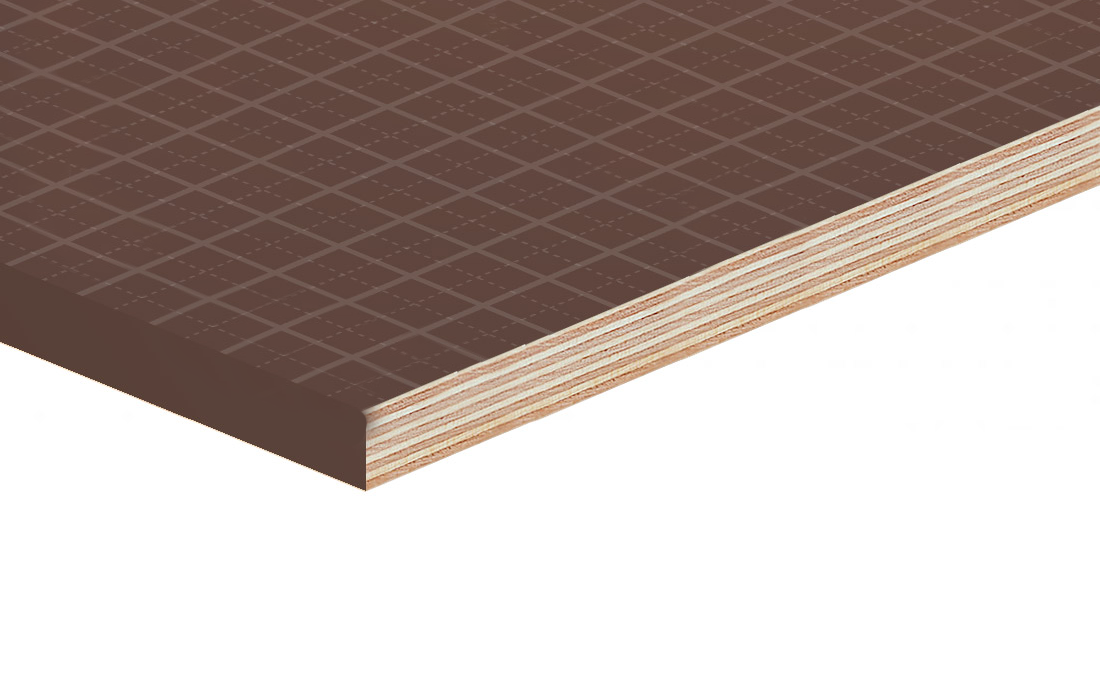

In addition to standard birch plywood grades, there are custom-manufactured types designed for specific applications. Two of the most common options are Birch Wire Mesh Plywood (F/W) and Birch Film Faced Plywood (F/F).

- Birch Wire Mesh Plywood (F/W): Engineered with an embedded wire mesh pattern, this plywood offers enhanced slip resistance, durability, and strength. It is ideal for flooring, ramps, scaffolding, and vehicle platforms, where safety and stability are crucial.

- Birch Film Faced Plywood (F/F): Coated with a protective film layer, this plywood provides excellent water and moisture resistance. It is widely used in concrete formwork, outdoor structures, and industrial applications requiring durability and longevity.

Birch plywood is a versatile, durable, and high-performance material, making it an excellent choice for industries such as furniture manufacturing, construction, and packaging. Its strength, flexibility, and reliability ensure outstanding performance in both structural and decorative applications.

By understanding the different grades and specific types of birch plywood, you can select the best option for your project, ensuring long-lasting results and superior quality.